Lithium-ion battery production processes that require gas detection

• Drying • EL filing • EOL testing • Separator Manufacturing

Gas Monitors for Electrode Manufacturing and Drying process

In the production of electrodes for lithium-ion batteries, NMP is used as a solvent. NMP will only vaporize at high temperatures during the drying processes. As concentrations of NMP build up, the risk of explosion increases. An ideal location to detect NMP is within the exhaust duct. By utilizing direct insertion design into the exhaust duct, detection of NMP will be at the center of the duct and able to withstand high temperatures and high concentrations.

Cell assembly – Electrolyte filing process

A variety of solvents are mixed in electrolytes, such as DMC, EMC, and DEC. These have the potential to explode if vaporized, so gas detectors are required.

SD-1GP

Concentration display

Diffusion Type

Explosion-proof

Cell Finishing – Testing Process

Every Lithium-ion battery is required to pass a test without emitting gas in a harsh environment. Combustible gas and toxic gas may be generated from the battery in the evaluation test process. Gas concentration monitoring is essential to prevent ignition and poisoning accidents during the testing process. When the gas detector detects the target gas, it is necessary to take outside air from the intake / exhaust damper to reduce the gas concentration in the test equipment.

GD-70D

Sample Draw

Separator production process

Dichloromethane (DCM) and other solvents are used for cleaning purposes in the production process of separators for lithium-ion batteries. For measuring low-concentration solvent gas and combustible gas, RIKEN KEIKI’s gas detectors are ideal solutions for separator processes.

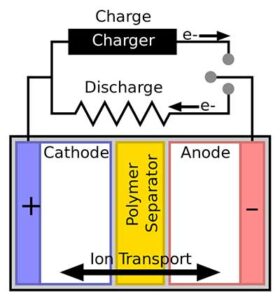

A separator is a permeable membrane placed between a battery’s anode and cathode. The main function of a separator is to keep the two electrodes apart to prevent electrical short circuits while also allowing the transport of ionic charge carriers that are needed to close the circuit during the passage of current in an electrochemical cell.

Separators are critical components in liquid electrolyte batteries. A separator generally consists of a polymeric membrane forming a microporous layer. It must be chemically and electrochemically stable with regard to the electrolyte and electrode materials and mechanically strong enough to withstand the high tension during battery construction.They are important to batteries because their structure and properties considerably affect the battery performance, including the batteries energy and power densities, cycle life, and safety.

SD-1GP

Diffusion Type

Explosion-proof

Case Studies

Since the birth of the lithium-ion battery, RIKEN KEIKI’s gas detectors have kept pace with technological innovation and have been used by many customers.

Continuous measurement enabled productivity improvement and cost reduction. Continuous measurement of solvent is essential for the separator manufacturing. Accuracy and maintenance free (no sensor replacement!) FI-900 was our choice after the consultation with Riken.

Frequent Sensor Sensitivity Deterioration.

After consulting with RIKEN Keiki with investigation, it was found that the cause was the silicon contained in the packing of the machine was melted into the gas. We replaced with the SD-2500 which has resistance against silicon which can damage the sensor. We were able to detect the NMP gas which has risk of causing huge damage to the factory as well as maintaining our safety.

NMP is collected and reused in the drying process.

If the concentration of NMP rises, there is a danger of explosion. SD-2500 is a direct duct insertion type, and the gas sensor can be placed to the center of the duct where the highest gas concentration. In addition, the explosion-proof design is capable to measure in high temperatures where NMP vaporized environment. Provides us a confidence to keep our safety.

SD-2600 is an ideal product for coating and drying process, close to 200℃

The SD-2600 Gas Detector is design for use in high temperature environments up to 200℃, while measuring NMP with high accuracy and reliability. Ensuring safety was our goal and product can be installed in the high temperature.

Suitable detector for low concentration gas.

We needed gas detector possible to measure PPM level for combustible and toxic gas at electrolyte filling process. Riken was able to adjust the range according to our request.

About RKI Instruments, Inc.

About RKI Instruments, Inc.

In partnership with Riken Keiki, RKI offers gas detection solutions for all production processes of lithium-ion battery manufacturing, which are typically high temperature environments. By utilizing direct insertion and heat resistant gas detection technology, accurate gas monitoring can be achieved in high temperature conditions often required by coating and drying processes.

Riken Keiki, a leading manufacturer of gas detectors with its own sensing technology for more than 80 years, has been involved in the research and manufacturing of lithium-ion batteries since the early stage of development. Over 10,000 gas detectors are in operation at the lithium-ion battery production sites around the world

About RKI Instruments, Inc.

About RKI Instruments, Inc.